Originally, this installation was designed to fulfill the Paris Climate Treaty and therefore was called the “Paris Reactor” (PR). The accelerating global warming of the Earth, which is recorded by objective measurements in recent decades, is already causing great harm to modern civilization, and in the future can lead to disaster. For example, melting glaciers will lead to sea level rise of more than 50 meters and flooding of territories with a population of up to a billion people during this century.

The world scientific community has undoubtedly recognized the cause of this phenomenon as the burning of carbon fuel and an increase in the level of CO2 in the atmosphere. After that, a social movement began to develop in the world for the conclusion of an international anti-carbon agreement by analogy with the 1989 Montreal Protocol, which allowed the Earth’s ozone layer to be saved by banning the production of chlorofluorocarbons. The difficulty of implementing the second global chemical and climatic ban as compared with the first is evidenced by the fact that back in 2015, investments in carbonless energy exceeded the entire world freon[1] market by 10 times, but… these costs did not lead to a reduction in emissions[2].

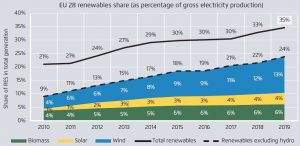

However, despite the huge resistance of hydrocarbon industry lobbyists, the implementation of renewable energy transfer programs is accelerating and with the active support of the leading world economies, and in the next decade the share of green energy will exceed 50% in the EU. In particular, attempts are being made to install systems for trapping CO2 in rock formations at classical thermal power plants. However, such an “upgrade” is very expensive and very limited in geography of application. And most importantly — it is only a temporary measure, since the EC has approved a plan for the complete rejection of fossil fuels. In addition, there is no 100% guarantee on the release of the “carbon genie” from the geological “bottle” in the event of natural and (or) man-made disasters. And in any case, 30% of carbon emissions remain outside the anti-carbon trend: aviation and small business. Since even the best developments do not allow these industries to maintain existing technological parameters (for example, the speed of airliners) without a multiple increase in prices.

The PR solves all of the above problems at the same time. The installation will continuously pass atmospheric air through itself and emit CO2 from it like a huge artificial tree. Consumables (fuel) will be solid household, industrial and (or) agricultural waste. Therefore, this technology simultaneously solves the problem of their disposal and purification of the atmosphere from smog and pathogenic bacteria and viruses. In the maximum version, the installation can be used as a source of technical and (or) drinking water. Productivity is up to 1000 kg. carbon/d. These parameters will create a new class of devices and a new market in the framework of the Paris Agreement and the EС programs. Personal installations for the first time in history will allow small businesses and even each person to take a real part in these global programs, including those with material benefits for themselves. Since one installation every two weeks will completely erase the annual “carbon footprint” of one person with a car, a wide range of marketing schemes will appear: leasing, leasing, an agreement to reset the personal carbon footprint of a person or organization, etc. This technology will open up enormous prospects for lawmakers, who will finally receive a concrete and understandable tool for approaching a carbon-free future. The obvious step will be the adoption of tax benefits for the turnover of CO2 under this program and the production of building materials from captured carbon. The appearance on the market of such equipment will create not just a market with a volume of more than $ 20 billion per year, but a new ideology. For example, airlines can rent equipment to collect CO2 in our common atmosphere and erase the carbon footprint from their aircraft. Now optimists only dream of reducing the rate of growth of CO2 in the atmosphere, and the serial production of PR… in 10 years will begin to reduce all CO2 in the atmosphere!

At the moment, the COVID-19 pandemic is forever changing civilization, just as the attacks of September 11, 2001 have forever changed the security industry, especially in aviation. Henceforth, regular sanitary treatment of the entire human environment will be a mandatory standard and two problems immediately arise. Although technologies for washing roads and buildings have long existed, the necessary increase in the consumption of detergents by 5-10 times will lead not only to huge costs, but also to an environmental disaster due to rapid accumulation in the environment. And the need to follow the “Wuhan fashion” will not only require washing clothes after each exit from the house, but also does not guarantee complete decontamination of viruses (plus not everyone is ready to switch to shoes that can be thrown into the washing machine).

The PR can solve all these problems at the same time, because in certain states of aggregation, CO2 is an excellent detergent. Until now, this technology has not been applied due to the high cost of such a washing machine, but the “new reality” completely changes priorities. Moreover, the classical technology of washing with water and drying ironing takes a lot of time. This will require putting a small laundry room next to each house (and office building?) And carrying several sets of clothes. They will require a connection to the water supply, sewage and electricity networks, the delivery of detergents, etc. Washing with CO2 will take several minutes, drying will happen faster… than you can take the clothes in your hands, and for most existing fabrics you can not iron after this procedure. The carbon dioxide laundries from the PRESENTGREEN designer will be completely autonomous (the source of energy may be household waste, industrial and industrial waste or other renewable energy sources) from water, sewage, and the supply of detergents, therefore they will be (conditionally) free to operate[3]. The enormous rate of change due to the pandemic does not immediately make it possible to correctly calculate this business plan, but a conservative assessment is quite possible. Already after the first cases of infection, Elabe[4] conducted a sociological survey in France, which revealed a fear of infection in 13% of residents. Obviously, now this is a guaranteed base of potential buyers of our technology. The smallest carbon laundry can serve 100 people. The business scheme of collective purchase and joint break-even operation (overhead costs within 100 $ per each co-owner per month) and 20% — 30% of profit at the stage of forming a new market leads us to the market size for such a model country as Ireland in the amount of 250 000 000 $[5]. The first supplier in the new market never receives less than 10%, therefore, the minimum estimate of his profit for 2 years is 75,000,000 $. The leasing business plan for potential users does not have a universal assessment, as it depends on the possibility of the manufacturer’s investment in equipment and operating points (an analogy between the taxi and car sales markets). The total cost for the manufacture of the first pre-production sample is 150,000 $ to -180,000 $[6]. The cost of 1 unit for serial production is 8,000 $ — 9,000 $.

In the near future, PRESENTGEEN holding participants will conduct laboratory tests to verify the deactivation of viral activity on objects of urban infrastructure using 100% CO2. However, tests of our colleagues reliably confirmed this ability in NaOCl[7]. This substance can be obtained in an additional unit to the PR using waste from industrial production and (or) quarries of non-metallic materials (conditionally zero cost). Market size in the “new reality” can be estimated by the geometric parameters and prices of existing disinfectants (simple detergents only wash away viruses and are not suitable for these purposes). Per person, on average, they will have to process 10 m2 outside the living limits and 30 m2 inside the house. The cheapest virucidal disinfector (bleach) for treating this area costs 0.2 $/ kg. per day. However, the continuous mass use of this tool is excluded for urban infrastructure for environmental and toxicological reasons. The price of analogues that do not have side effects on human health and the environment is at least 1 $[8]/ per day. Total, the potential market size of Ireland is at least 1,800,000,000 $ per year in current prices of analogues. The appearance on it of a product with a 50% discount and at least 50% profitability if only 1 (one) % of the market is occupied has a profit potential of 7,500,000 $ per year. Investments to start the installation of such a capacity of 1,200,000 $ -1 500,000 $, and for a pilot installation with the goal of testing the technology 90,000 $. A big plus of this technology is the ease of storage and transportation of the substance (in contrast to CO2).

For the production of equipment samples adapted for serial production of one or two types (see table), it is required to complete pilot work on the basis of a complete and (or) simplified version of PRESENTGEEN’s installations. PR is the «basic element» of the whole «designer» to solve a wide range of tasks. A conservative estimate of the market value of this technology is 10 million $ at a startup level with existing samples. In the case of the start of production, a conservative estimate of profit is 24 million $ per year.

P.S. And this is not the last pandemic, but only the first!

[1] According to the International Energy Agency and the expert group at the Vienna Congress (supplement to the Montreal Protocol), approximately $ 32 and 320 billion.

[2] The coronavirus pandemic is a force majeure event.

[3] Accurate accounting of service costs, depreciation and other similar costs is possible only with a specific contract, however, these operating costs do not exceed 20% of classic water laundries.

[4] More relevant and large-scale surveys in the EU at the time of writing this document were not conducted 03/27/20.

[5] In this business diagram, a manufacturer makes a profit once by selling equipment.

[6] These costs do not include a source of CO2 (PR).

[7] H2O2 (hydrogen peroxide) is also effective, but its production belongs to the group of toxic and explosive and therefore is not considered in the ideology of PRESENTGREEN.

[8] Prices before explosive consumption growth due to the coronavirus pandemic.